RR Rack Conveyor Dishwasher

The advantage of RR rack conveyor dishwasher is that they can be adapted to suit any space and any operation. If you have space constraints, then a rack conveyor machine is a good proposition. Rack conveyor dishwashers can be fitted with pre-sorting and segregating tables and conveyors giving a very efficient and versatile operation. Ideal for operations with many varied items of which many need to be placed into racks.

Relying on years of heavy duty industrial washer experience, the RR range (previously known as the RX range) will suit the most demanding wash up operation. From the no-frills RR 108 to the massive RR 405, the RR range has a model to suit your operation.

RR rack conveyor dishwasher:

Description

Optional Items:

- Steam condenser

- Heat Recovery units which allows to supply the machine with cold water (inlet water temperature between 8°C and 15°C) and to significantly save energy at the same time. The steam produced by the machine operation (otherwise lost in the room) is recovered and led through the heat exchanger (air – water). The energy of the steam is used to preheat up to 45°C the inlet water with a consequent reduction of energy consumption.

- Detergent Dispenser which means that chemicals are able to be connected to the machine and are automatically dosed and injected into the wash cycle of the machine

- HACCP supervisor which monitors and records the machine’s vital statistics

- Automatic self cleaning cycle

- Blowers

Benefits

- Standard 50x50cm washing racks are transported through the various stages by means of a stainless steel ratchet drive. The drive is fitted with a safety clutch.

- Insulated doors which help to maintain a constant temperature in the washing chamber which in turn allows for a reduction of power consumptions for the boiler heating elements.

- CPF which is a device that allows for user to easily adjust the water pressure in the prewash or wash phase depending on each users needs.

- AIS 304 and 316 stainless steel which allows protection from aggressive cleaning agents and salty water.

- The standard machines are electrically heated, steam is an option.

- Wide inspection doors give full access to the wash zone.

Downloads

You may also like…

-

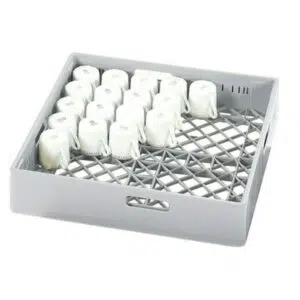

Commercial Dishwasher Tray Rack 50 x 50, 500mm x 500mm

$84.00 -

Superwash Detergent 10 Litre Drum

$96.30 -

Extended Warranty

-

Preventative Maintenance and HACCP Testing

-

RR 108 Rack Conveyor Dishwasher

-

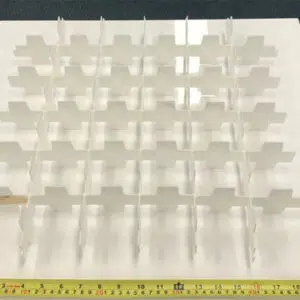

Commercial Dishwasher Divided or Compartment Glass Rack 50 x 50, 500mm x 500mm

-

Commercial Dishwasher Open Rack 50 x 50, 500mm x 500mm

$84.00