Underbench Bottle Washer RBW50U

The newly designed RBW50U underbench bottle washer by Rhima improves hygiene and cleanliness as well as improved efficiency. For example if glass milk bottles are not cleaned and sanitised properly or at all and milk residue remains, this creates a food safety hazard for customers and the dirty bottles have to be thrown out due to their contamination risk.

Industrial bottle washers exist but most are geared up for very large production runs in fully automated environments. Smaller bottle washer/sanitisers are available also, but they are mainly aimed at the laboratory market with low capacities and long cycle times. The brief was to design and build a washer/sanitiser that would wash and sanitise to a HACCP program acceptable level, ease of use, a suitable and viable capacity while at the same time minimising energy and water consumption. The machine had to be commercially viable for use in different similar re-useable environments.

These bottle washers can wash any style and type of bottle from small returnable cocktail bottles to larger milk bottles.

*Please note: images on left hand side of screen show the inside of the pass through bottle washer

Customers using a glass bottle system is designed to be a circular process for waste elimination (eliminating both recycling and landfill). All (clean) returned bottles that the customer receives are rewashed, sanitised and refilled inside their processing facility.

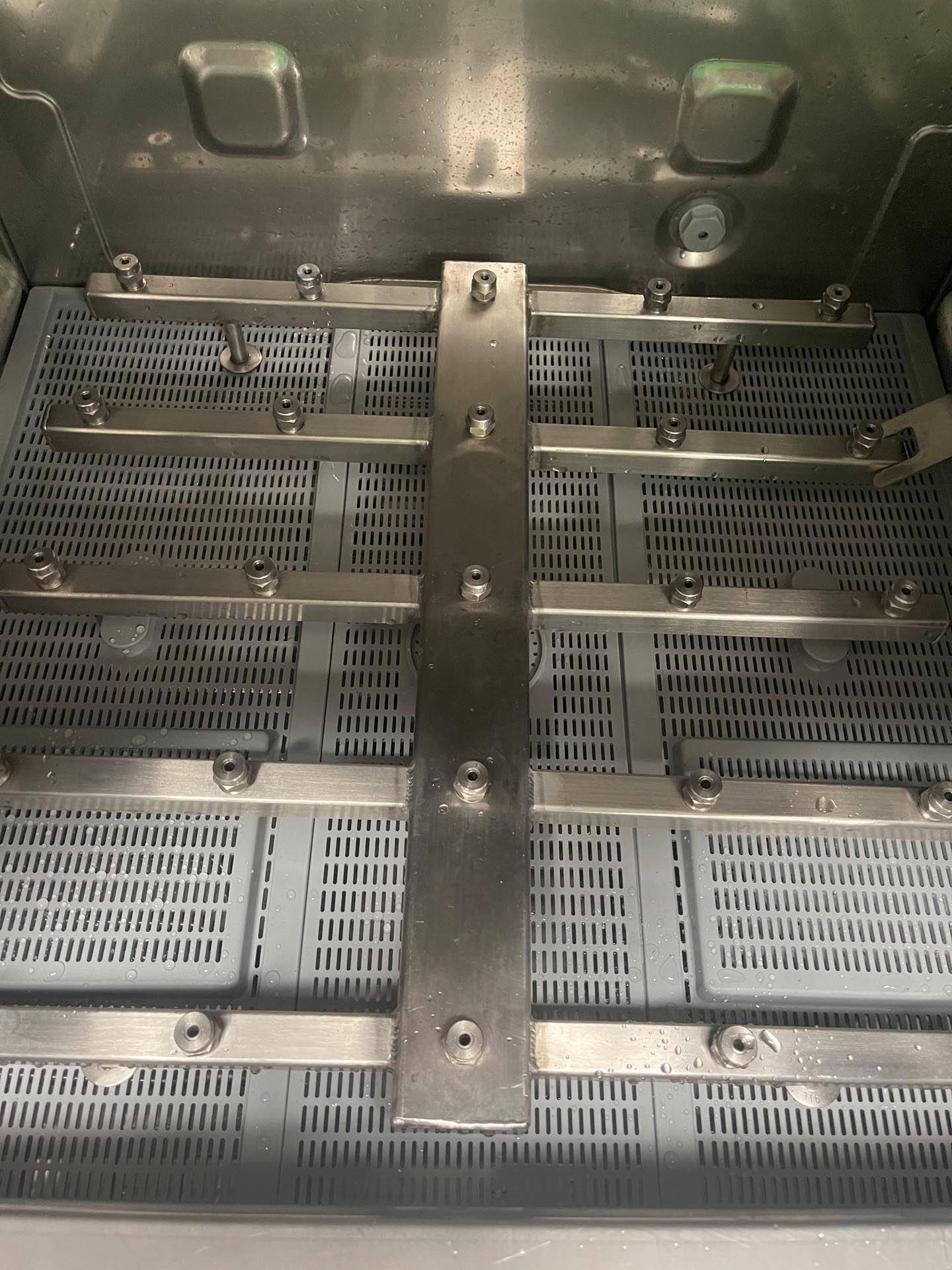

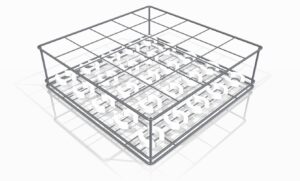

The RBW50 underbench bottle washer uses a rack to hold the bottles and has a dedicated nozzle rack to ensure that water goes directly into the bottle. This guarantees that each bottle is cleaned and sanitised. There is a rotating wash arm that goes around the top to clean the outside of the bottles.

The washer allows the reusable glass bottles to be available on the market. Without the ability to wash and reuse them hygienically sustainable ventures wouldn’t be possible.

- Thermostop system that meet HACCP requirements

- Wash/rinse arm with easy to remove & clean nozzles

- Door safety switch

- 3 cycles (wash only, rinse only, wash & rinse)

- Built-in detergent & rinse aid dispenser

- Separate control panel can be wall mounted dimensions - 250 x 200 x 90 mm H

- Standard rack fits 25 bottles of any shape up to 95mm diameter

- Drain pump to allow for easy connection to drain

- Heavy duty, commercial grade construction

- Power supply: 240V

- Total power: 3.2kW

- Total current: 15 AMP

- Wash tank capacity: 20 ltrs

- Water consumption (wash & rinse cycle): 20 ltrs

- Rinsing temp approx: 75 degrees celsius

- Rack size: 500 x 500 mm

- Tallest washable item: 33 cm

- Weight empty: 55 kg

- Water connection (Hot): 3/4" hose

-

Does my machine comply with HACCP guidelines?

Rhima has developed a unique monitoring program that takes safety, hygiene and operational conditions into account. Once correctly setup your machine will comply with HACCP guidelines. At least once per year we recommend to do a safety hygiene test on the dishwasher. Rhima technicians are specially trained in carrying out preventative maintenance and HACCP testing on Rhima equipment. This includes temperature checks with a calibrated thermometer, residual protein swabs (before and after) as well as full preventative maintenance on the machine.