For food producers, food safety isn’t just a buzzword—it’s the backbone of your business. Foodborne disease outbreaks can have a devastating impact, not only on public health but on a company’s reputation and bottom line. It’s a risk every food manufacturer must take seriously.

The Sobering Reality of Food Contamination in ANZ

The numbers here in Australia and New Zealand tell a sobering story. A 2022 report commissioned by Food Standards Australia New Zealand (FSANZ) found that Australia experiences approximately 4.67 million cases of foodborne gastroenteritis each year, with a total cost of AUD $2.1 billion to the economy. In New Zealand, there are an average of 500 cases of food poisoning each day.

The most common culprits are:

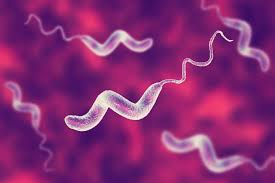

Campylobacter and Salmonella, which account for 60% and 34% of cases in Australia, respectively.

A visual depiction of Campylobacter and Salmonella.

Case Studies in Brand Damage

The financial impact of an outbreak—from fines and product waste to brand damage and even bankruptcy—can be ruinous for a food producer. We’ve seen how quickly things can go wrong with real-world examples in Australia and New Zealand.

- Garibaldi Smallgoods: The company went into liquidation in 1995 following a food poisoning event caused by contaminated sausage. The incident led to one child fatality and 23 children being hospitalized.

- Listeria Outbreak: In September 2023, a Listeria outbreak in the eastern states of Australia was linked to a commercial shredded chicken breast product served in hospitals, prompting public warnings.

- Salmonella in Eggs: A major egg recall in 2019 led to a farm euthanizing its entire chicken population to prevent further contamination. The farm, which once supplied almost 10% of the national egg market, has since closed.

These incidents highlight the critical importance of a proactive approach to food safety. The foundation of this is a robust food safety workflow.

The Role of Industrial Dishwashers in Food Safety

While a comprehensive food safety workflow includes testing, you can’t test your way out of a sanitation problem. Proper cleaning and sanitation are essential for preventing microbial contamination, which can occur at any stage of the food supply chain.

This is where the right equipment makes all the difference. Rhima’s industrial dishwashers are an essential tool for any food processor.

Rhima’s industrial bin washers provide a reliable and thorough cleaning solution for food processing.

Investing in Prevention: How Rhima Helps

By ensuring that food handling equipment and tools are properly cleaned and sanitized, our machines help reduce the risk of disease transmission and prevent contamination of your food products. They can wash a large number of items quickly, with a typical cycle lasting only one to four minutes. This allows your team to focus on their core tasks rather than spending precious time on hand-washing, all while guaranteeing you meet food safety and health standards.

At Rhima, we believe that investing in high-quality, reliable sanitation equipment is one of the most effective ways to mitigate the risks of foodborne illness. It’s a step that not only protects your customers but also safeguards your brand and ensures the long-term sustainability of your business.

Sparkling clean, sanitized equipment from Rhima’s industrial’s washing machines.