In the modern Australian hospitality scene, reusable bottles are everywhere. Whether you’re serving sparkling water in elegant glass vessels, craft beer in returned bottles, or kombucha, the commitment to sustainability is clear—and it’s a great look for your brand.

But have you considered the operational reality of keeping those reusable bottles actually clean?

If you rely on manual cleaning, the answer is likely no.

A fascinating (and slightly horrifying) BBC Future article, Are you cleaning your water bottle enough?, highlights a startling fact: water inside reusable bottles can escalate from around 75,000 bacteria per milliliter in the morning to over 1–2 million per milliliter within 24 hours.

For a commercial operation, this isn’t just an anecdote—it’s a major compliance and reputation risk. In a fast-paced environment where time is currency, manual scrubbing is not just slow; it’s dangerously inconsistent.

Are you cleaning your water bottle enough? Written by Jessica Brown, BBC

Time is a Critical Asset: Stop Paying Staff to Scrub

Manual bottle cleaning is a black hole for labour hours. Every minute spent scrubbing a neck or checking a dried bottle is time taken away from customer service, food prep, or table turnover.

The Solution: Implementing commercial bottle washers automates this slow, inconsistent process. The efficiency gain is immediate: staff simply load the dedicated racks, and the machine handles the entire high-volume, repeatable process. This is where your investment pays for itself—not just in health compliance, but in real, quantifiable labour savings and operational consistency.

Guaranteed Sanitisation: The Crucial Temperature Check

The danger with manual washing isn’t laziness; it’s physics. Bacteria, especially pathogens that cause human infections, thrive around body temperature. Experts recommend using water over 60°C (140°F) to kill most pathogens effectively.

Can your kitchen staff consistently maintain that temperature during a busy service? Probably not.

This is where the engineering of a dedicated bottle washer becomes non-negotiable. Our unit’s integrated Thermostop system ensures the final rinse temperature is consistently maintained between 70°C – 80°C. This high heat achieves 100% sanitisation, meeting or exceeding stringent HACCP requirements for every single item that passes through. Plus, the system promotes thorough drying to eliminate the moist environment microorganisms prefer.

The Smart Investment: Why Multi-Purpose Matters

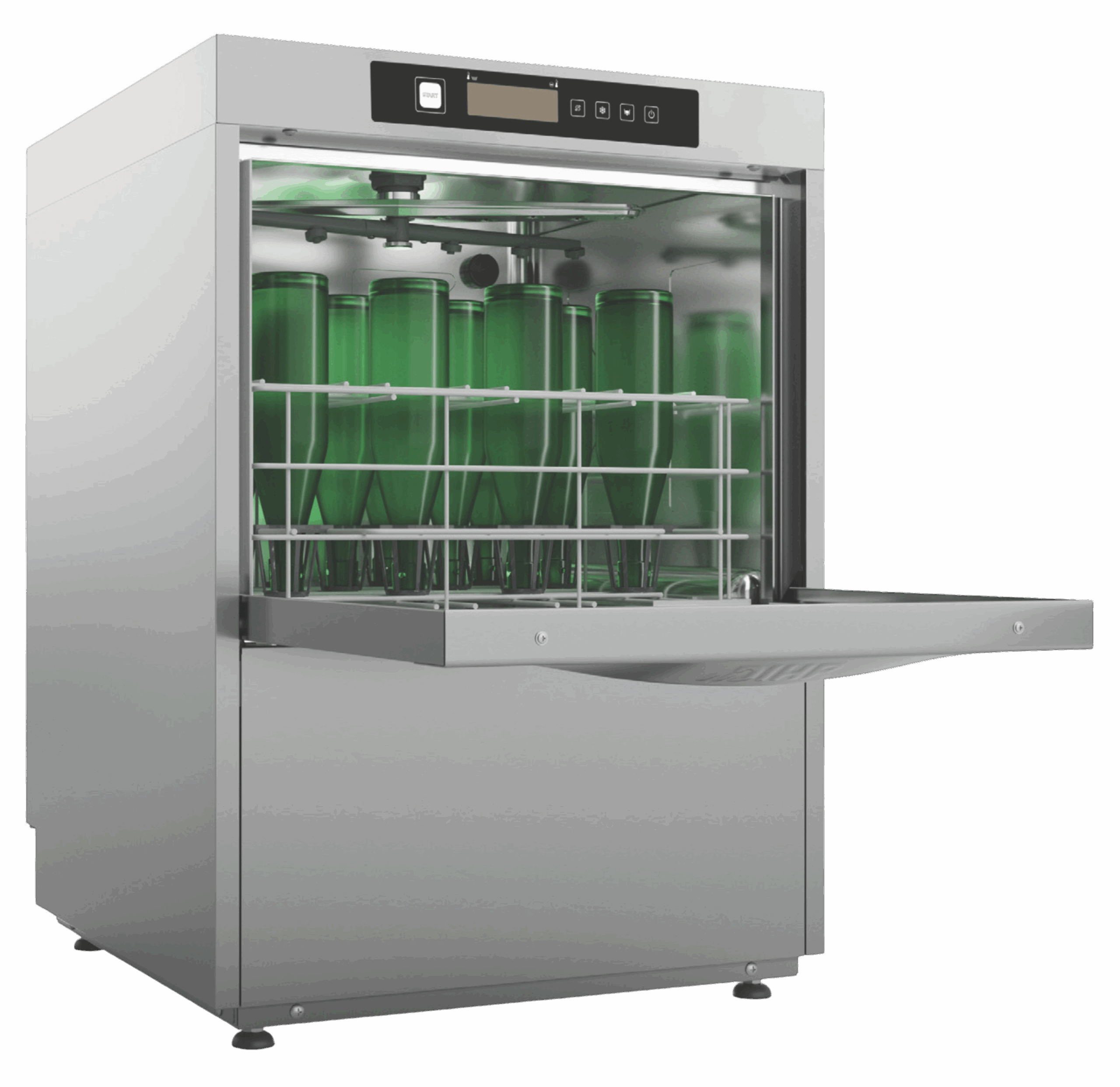

While we’ve focused heavily on the bottle washing capabilities—a new requirement for many businesses—the equipment also offers complete flexibility.

The Rhima CBW50 isn’t just a bottle washer; it’s a high-performance combi unit. By simply swapping out the specialized bottle racks for alternative trays, the machine seamlessly transitions to handle all your standard crockery, cutlery, and kitchen items.

This dual-purpose design means you are making one smart investment that eliminates hygiene risks and operational bottlenecks across your entire wash area. You get proven operational excellence with minimal water and energy usage, all wrapped into a single, reliable machine.

Depiction of Rhima’s Bottle Washers multi purpose capabilities

Ready to Eliminate Bacteria and Bottlenecks?

It’s time to move beyond the manual brush and rags and bring food safety into the 21st century. Make a smart investment in your team’s efficiency and your customers’ safety.

You can explore the full specifications of the Rhima commercial Combi Bottle Washers on our website today.